Roombar

Reverse engineering an old remote-controlled tank into a modern, functional remote-controlled vacuum cleaner

Introduction:

As part of a university group assignment at the University of Leeds, we transformed an old remote-controlled tank into a modern vacuum cleaner by repurposing its motors and gearboxes.

To meet our target audience's needs, we identified customer needs and created a user persona. This guided the creation of a bill of materials to assess available parts and materials for our new design. We then explored different architectures for the vacuum cleaner, focusing on optimizing suction power and maneuverability. Once we decided on our design concept, we created a detailed CAD model of our new product. This allowed us to visualize the final product and make any necessary adjustments before building a physical prototype.

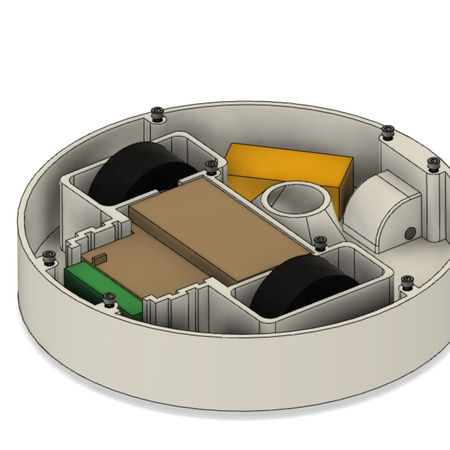

Chassis Design:

Our design repurposes the drive motors of the tank to power the wheels and an additional DC motor with a speed of 11,000 RPM to power the fan. The fan moves air from the intake port to the dust-collecting bucket, where a filter traps dust and other particles.

Electronics Design:

As the H-bridge circuit and controller receiver system of the RC tank were no longer functional, we were forced to create our own electronics design. The circuit included an H-bridge - an electronic circuit that allows the polarity of a voltage to be switched, enabling a motor to spin in both directions. Our design is fueled by the BTLE module in slave mode, controlled by the other BTLE module attached to the controller in master mode which sends the signals of the push buttons to control the movement of the vacuum cleaner.

Cost:

The cost for the 3D printed parts, as stated in the bill of materials, is £21.80. The driving system was reused from the tank; however, the electrical circuit was damaged, forcing us to make a new one, resulting in a cost of £17.90. Therefore, producing a final expense of £38.98.

Our innovative approach to reverse engineering enabled us to create a product that not only meets the needs of our customers but also showcases the endless possibilities of reusing existing technology to create something new and useful.

Statistics

15

Components

38.98

Pound (£)

11000

RPM (Fan Speed)

Project Gallery