Carbide

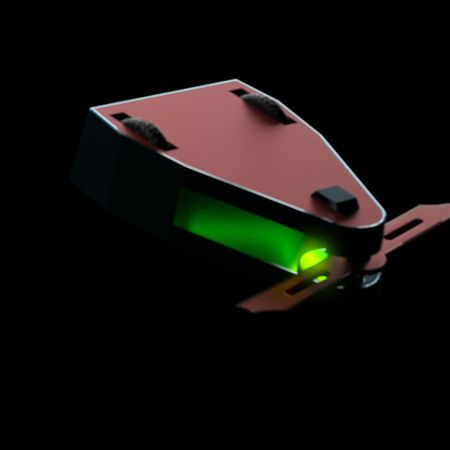

Carbide is a realistic 3D model of a robot created to compete in the infamous "Robot Wars"

This project was crafted during a placement year endeavor, where our team was tasked with constructing a lifelike robot model for participation in Robot Wars. We adhered to specific guidelines, including a weight limit of 110Kgs and maximum dimensions of 2.0 x 1.5 x 1.2 metres. Our goal was to meticulously design the model using SolidWorks, selecting suitable materials to provide an accurate representation within the given parameters.

Design Concept:

The Design Concept for Carbide has been carefully considered putting practicality above anything else, which consequently made design considerations easy which helped lead us to our final concept.

Our primary weapon is a 25kg blunt spinning bar made of titanium with plain carbon steel on the edges, capable of spinning at 5000rpm.

This weapon was designed based off calculations which put the structural integrity and effectiveness of the weapon as a priority

A powerful drive system was crucial when designing the blade as we needed high-performance motors as well as a drive chain system to ensure a higher torque and greater impact.

The internal components have been specifically placed to minimize the risk of mechanical failures during battles, ensuring it could perform at a high performance to withstand combat.

The shape of the robot is optimized to position this weapon for maximum impact on opponents. The spinning bar has been mounted in the front and centre of the robot to ensure it can deliver strikes to opponents' body.

Design Specs:

Material Selection: Choosing high-quality materials for critical components such as the body, blade and wheels ensures durability and resilience during combat. Carbide uses materials such as titanium and steel for the blade, aluminium alloys, and rubber to withstand intense battles.

Reliability: Reliability is important in combat robotics, where mechanical failures can mean defeat. Carbide’s design incorporates a two-way drive system to allow it to move whatever side it gets flipped on, this system is in use to minimise the risk of any crucial failures during matches, ensuring consistent performance throughout the competition.

Performance Optimisation: Every aspect of Carbide’s design would has been optimised for maximum performance in the arena. This includes aerodynamic shaping, weight distribution for stability and control, and weapon systems drive chain to deliver the most effective strikes against opponents. Multiple revision changes had to take place to get to the final optimal design to comply within the weight regulations.

Compliance with Regulations: Compliance with competition regulations is essential to avoid disqualification. Carbide's design has been carefully vetted and checked to ensure it adhered to size, weight, and weapon power restrictions specified by Robot Wars rules and regulations.

Simulation Testing:

To prove our concept of Carbide's ability to withstand substantial attacks during combat, we completed a series of static simulation testing within SolidWorks.

The first simulation we conducted demonstarted a distributed impact of 10,000N into the rear of the outer 8mm aluminium shell. - The results showed a maximum stress of 54.5MPa, where as the yield strength of the material is 125MPa, depicting Carbide's ability to withstand heavy blows.

The second simulation we conducted demonstarted a concentrated impact of 10,000N into one point of the rear of the outer 8mm aluminium shell. - The results showed a maximum stress of 93.23MPa, which is still lower than the shell's yield strength.

Similar simulations were run with impacts on the top of Carbide's body - The results further proved Carbide's resiliance against heavy blows in combat.

Costing:

Using the cost of the materials used within SolidWorks, we were able to determine that this entire model of Carbide could be created at a cost of £3128.33

Statistics

3128

Pound (£)

5000

RPM (Blade Speed)

125

MPa (Yield Strength)

Project Gallery